- Export Business

- high performance & advanced materials and its product

- ultra precision parts & components

- innovative technology products

Non-Productive Material/Capital Asset Procurement Management Consulting Project: case study of procurement consultation for imported precision machining center project

A case study of procurement management for a new manufacturing center in a private manufacturing company in Anhui Province

Client Enterprise: Anhui Auto Parts Co., Ltd.

Main business: Processing and manufacturing of key automotive parts

Project scope: precision machining center

Target: 38 new precision machining centers

Project Initial Situation SITUATION

Potential customer needs of client companies

Customer enterprise capacity planning

Customer Product Category

Customers provided 5 internationally renowned machining center brands

Purchase budget

…

Consulting tasks TASK

The selected machining center has a variety of flexible processing capabilities;

Cannot exceed established budget;

Equipment indicators are not lower than the international average level [eg, OEE is not lower than 85%];

Provide necessary technical operations and maintenance;

Delivery time: start to deliver in batches within 3 months;

After-sales service: response time is within 48 hours;

…

ACTION / SOLUTION

Hay Think led the project procurement team within the client company;

Hay Think provided three other internationally renowned machining center manufacturers to participate in the bidding based on rich industry experience;

Guide customers to compile purchasing technical specifications according to specific technical specifications templates of machining centers;

Neutralize technical requirements, and try to avoid certain special thresholds to exclude other competitive participation;

Hay Think composes a structured inquiry list and compiles all customer requirements into inquiry requirements;

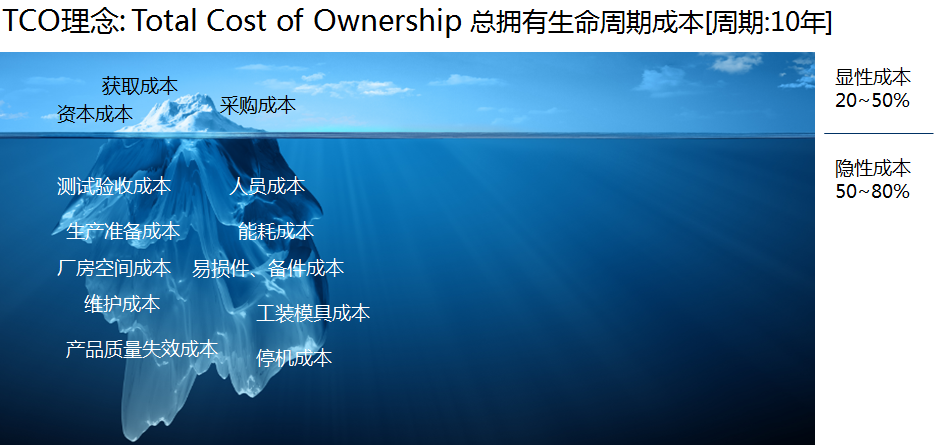

Require all machining center manufacturers to provide TCO calculation process;

Require all manufacturers to provide after-sales service charging standards and response speed;

Includes the brand, model, delivery cycle and corresponding price of all key parts and wearing parts;

After-sales labor price

Response time for fault type

…

Set the consumption CAP of spare parts and consumables within 3 years after installation and acceptance of the equipment;

After receiving the manufacturer's quotation plan, visit the customer's site to analyze the accuracy and authenticity of the data;

Preparation and implementation of strategic procurement negotiations;

Matrix supplier evaluation and selection based on supplier inspection reports and supplier quotation plans and the results of strategic procurement negotiations [based on equipment lifecycle TCO]

Signing of strategic procurement contracts [including QAA …];

TCO protocol of equipment;

Equipment pre-acceptance;

Equipment installation and commissioning specifications;

Consumption tracking of equipment spare parts and wearing parts;

Equipment performance index recording and tracking;

TCO data record of equipment;

Supplier key performance assessment;

…

Project Results

The actual equipment purchase amount is 20% lower than other customers on average

Defined TCO and signed TCO agreement, the total equipment life cycle cost is about 30% lower than the industry average;

The manufacturer's inventory of spare parts of the equipment is borne by the manufacturer, which greatly shortens the procurement cycle of spare parts and reduces the risk of shutdown;

The cost of after-sales service is about 50% lower than other customers, and the delivery and cost are completely controllable;

The OEE of the equipment is higher than the industry average;

The manufacturer's drawings were obtained for conventional parts;

The machining center chooses Germany's world-renowned brands, which is flexible and highly automated, and has greatly improved efficiency;

The product has high precision, high consistency of quality stability, and greatly reduces the cost of quality failure;

Hay Think's advanced procurement management consulting services are creating value for many companies …