During my time as a purchasing manager in a Fortune 100 foreign company, I interviewed many candidates for procurement engineers during the process of recruiting procurement engineers. I often ask them a very simple question:

How did you RfQ for your previous work?

Many candidates think this question is too low. What is there to learn about the inquiry? In fact, the knowledge of procurement inquiry is very large. In the actual procurement behavior, most local companies' procurement is still extensive management. Due to the lack of effective management of procurement requirements, lack of information, and information errors, suppliers have repeatedly requoted and communicated Inefficiency is very common. Sometimes the project has been running for several months, and it is found that a lot of information is wrong, causing everything to start from scratch, wasting a lot of resources, and more importantly, the delay of the project will affect customer satisfaction, and then affect To the market.

Mature inquiry management will make the procurement process extremely efficient, avoid repetitive and inefficient communication, and speed up the project development process.

The following briefly describes how the inquiry management of Volkswagen Purchasing Center is carried out:

Project Demand Management

Before the inquiry, all the required information of the project procurement should be structured and modularized.

Basic information of the project

Customer project requirements information

Information on special project requirements for companies

Project development, technical requirements information

Information on project quality management requirements

Demand information of the project logistics department

Information of the project purchasing department itself

…

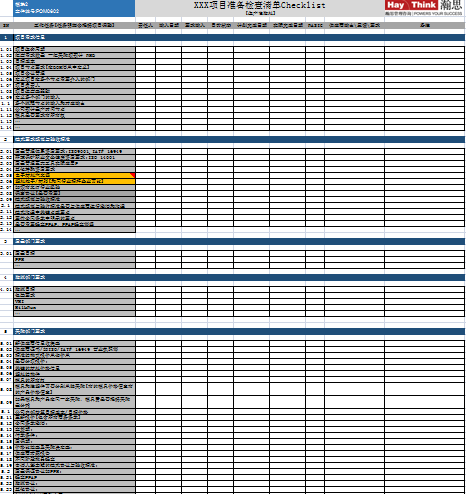

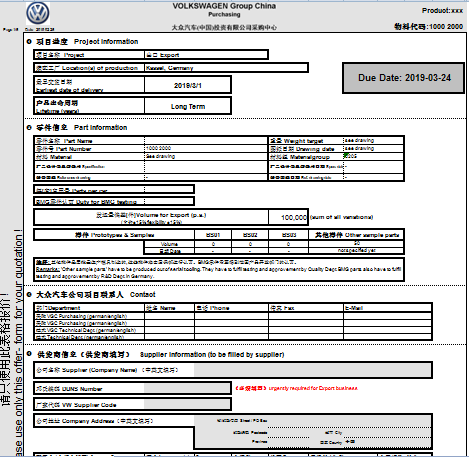

Standard RfQ Checklist

The above demand information is integrated into the inquiry list. In fact, the inquiry list is equivalent to a list of questions. We list all the information and questions that need to be known in one form at a time. The more you ask, the more information you get. Adopt standardized question forms to allow suppliers to answer according to their actual production. In the future, structured cost quotations and various terms will be more transparent and horizontally comparable.

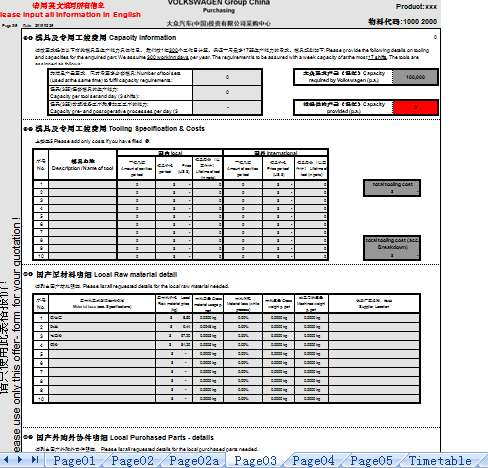

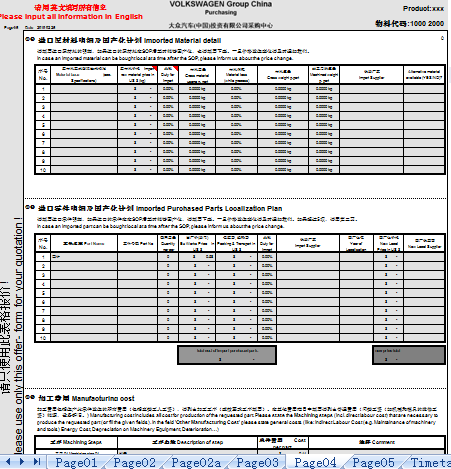

The standard inquiry checklist includes:

Basic information of the project

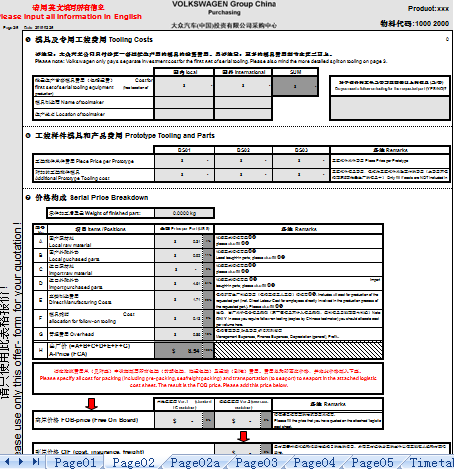

Structured cost [Structured cost data of product, cost data of mold, tooling, etc.

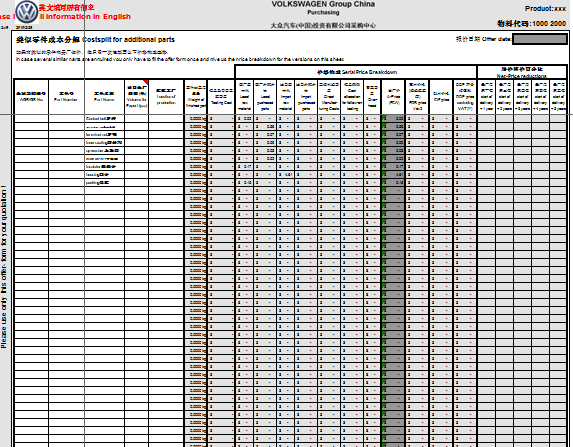

Cost breakdown for individual parts

Cost breakdown of domestic materials and parts and imported materials and parts

Localization plan of imported materials and parts and breakdown of domestic processing fees

Terms and conditions of purchase [omitted]

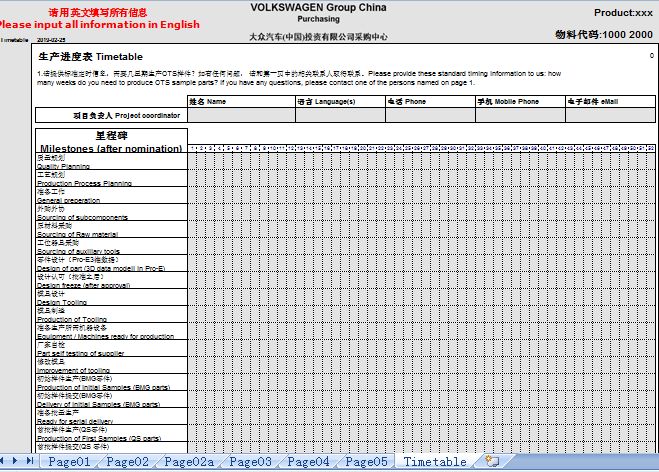

Project schedule

Then send this standardized structure cost inquiry to 5 ~ 8 suppliers, and they will prepare relevant information and data.

In this process, all the information opportunities required for project procurement are included. Unlike many non-professional buyers, they have just sent out an inquiry. Due to incomplete information, suppliers ask a question and they answer a question, which results in inefficient communication.

After obtaining all or most of the quotations, due to the use of a unified template, everyone's project information and cost structure became extremely transparent and comparable.

Lay a solid foundation for subsequent purchasing decisions.