Global Sourcing & Procurement

Outsourcing Service Center

In China

Export Business on Advanced Material & Precision Parts

Strategic Cost & Negotiation Management

As a Strategic Sourcing & Procurement Expert, to achieve cost saving through strategic negotiation with suppliers is routine tasks and are the basic skills, but without knowledge on cost struture and cost modeling would be a disaster.

Purchasing big projects and negotiating large quantities and large amounts of pproducts and materials, or negotiating annual price reductions, etc. are the daily work of the sourcing & procurement department, and are also an unavoidable challenge for many procurement colleagues.

As market competition intensifies, the purchasing department of enterprises is facing more and more pressures and challenges from reducing costs. If you face these challenges, easily win them?

Negotiation Power [POWER]

The bargaining power [POWER] is the most core element to achieve the established goals of procurement negotiations. The bargaining power comes from two aspects:

External environmental data information for procurement negotiations [accounting for about 70% of negotiating power]

Negotiator’s internal psychological and external environmental information processing and response capabilities [accounting for about 30% of negotiating power]

Preparation for Strategic Sourcing & Procurement Negotiations

Based on the analysis of a large number of classic cases of strategic negotiation and the research of international authoritative institutions on negotiation theory, the conclusions are drawn:

90% of the successful and efficient process of negotiating art takes place during the negotiation preparation stage!

The negotiation preparation process is the process of collecting the required information and using information analysis tools to turn it into a negotiation power [POWER]!

60+ Cost Saving & Value Creation Strategies and Tools in Strategic Sourcing and Procurement

Hay Think would devleop and select the right Sourcing & Procurement Strategies and Tools based on the categories and suppliers.

Strategic Cost Management: A Structured Approach to Cost Reduction

Price Analysis

Market Structure

Ecnomic Conditions

Pricing Strategies of Supplier

Makert-driven Price Models

Using the producer Price Index to Management Price

Cost Analysis Techiniques

Cost-based Pricing Models

Product Specifications

Estimating Supplier Costs Using Reverse Price Analysis

Break-Even Analysis

Total Cost of Ownershop[TCO]

Building a Total Cost of Ownership Model

The Importance of Opportunity Costs

Important Factors to Consider When Buidling a TCO Model

Collaborative Approach to Cost Management

Hay Think Strategic Sourcing & Procurement Negotiation Skills Features

Hay Think’s Strategic Sourcing & Procurement Negotiation skills focuses on the set of procurement negotiation goals, systemic procurement of external information collection which based on the TCO concept at the beginning of the project, and acquisition of negotiation power based on the negotiation goals and advanced information analysis model tools Use the information about the inferior environment through information and information analysis tools to find out the corresponding solutions and then transform the inferiority or even into the negotiating power, so that the negotiating power of both sides undergo a fundamental change. The scientifically planned negotiating process and logic The negotiation process is controlled so as to achieve the established negotiation goals.

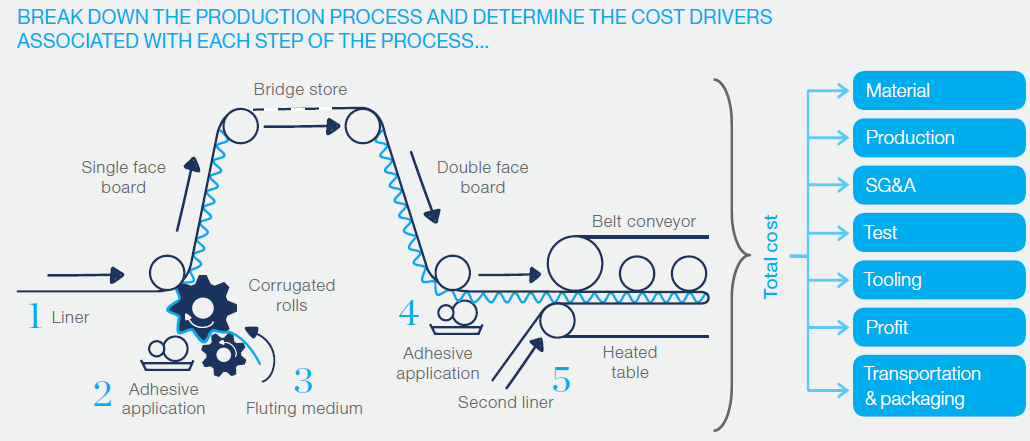

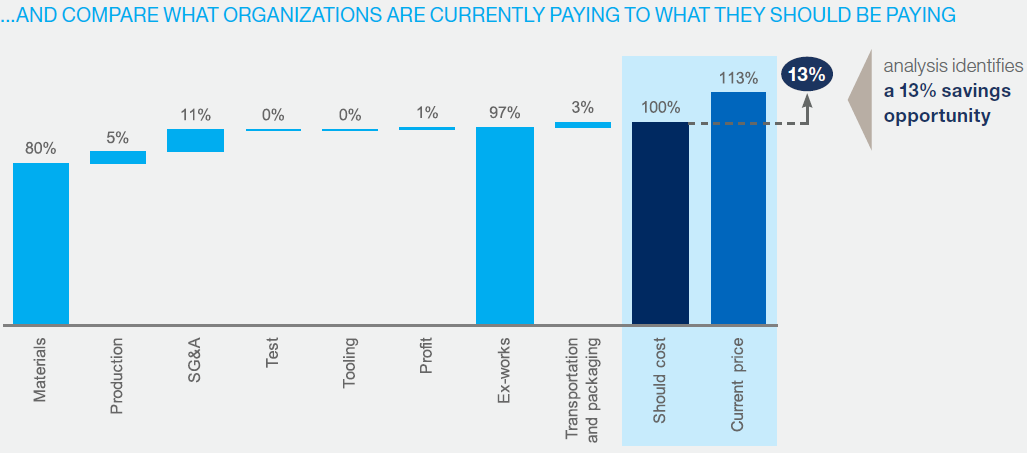

Cost Driver Modeling

Without visibility into what contributes to each product`s manufacturing and delivery costs, it is difficult for companies to identify which parts of their procurement process present cost reduction opportunities.

Cost Driver Modeling solves this problem

Cost Driver Modeling enables procurement andproduct de velopment leaders to analyze a product`s underlying cost structure to identify efficiency opportunities in purchasing,production, delivery, and design.

by providing a database of input costs, a suite of analytical tools that prioritize cost-saving initiatives across the production process, and a team of experts that analyzes competitor products and facilitates supplier negotiation workshops. By analyzing every aspect of the production process, Cost Driver Modeling uncovers exactly which procurement or design changes will result in the greatest savings.

Cost Driver Modeling is a collaborative tool that rapidly determines should-costs for items through an existing library of cost models and custom-model building capabilities. These models are populated by data from curated cost databases, insightsfrom Hay Think`s network of category experts, and inputs from supplier workshops to calculate should-cost for specific items and whole portfolios. Cost Driver Modeling provides a sustainable solution to managing product costs year over year.

Sample

Parametric modeling

Bringing cost transparency and analysis to complex portfolios and large supplier bases

What is it?

The Cost Driver Modeling Solution offers a parametric capability which uses a flexible model to calculate savings opportunities for entire categories of items based on a few parameters such as dimensions, materials, or finishing. The parametric capability can also be used to determine costs of indirect spend such as temporary labor or freight load.

This feature supplements the Cost Driver Modeling`s ability to conduct complete pricing teardowns for a couple items at a time.

What impact does it generate?

• Increases visibility of total spend breakdown and enables higher confidence for supplier negotiations, resulting in higher savings

• Allows procurement to analyze entire portfolios of parts quickly for organizations with complex, fragmented categories and multiple suppliers

• Brings a level of ease and depth of analysis to understanding costs for organizations with large portfolios of items

Cost Driver Modeling

Strategic Sourcing & Procurement Negotiation Panel

HOW COST MODELING HELPS CLIENTS

Visibility

Our modeling capability improves transparency around total spend breakdown, helping leaders feel confident in supplier relationships and capture higher savings.

Agility

We enable procurement to analyze entire portfolios of parts quickly for organizations with complex, fragmented categories and multiple suppliers.

Depth of analysis

Parametric modeling makes it easy for organizations with large portfolios to visualize, analyze, and optimize their costs at a granular level.