Forging can not only shape and obtain a certain mechanical strength, but more importantly, it can exclude impurities in the metal, make the composition uniform and dense, and sometimes refine the grains, thereby greatly improving the quality of the metal and the toughness of the sword. Metals get good overall performance.

Today, the forging process is still used in the field of combat, such as fighter jets, warships, and missiles.

WXPK entered the military industry in 2013. In the aviation field, Parker New Material products have covered multiple models of aeroengines in service and in research; in the aerospace field, WXPK New Material has participated in the "Long March Series" and "Expedition Upper Class" and other launch vehicles and many Development and matching of model missiles; in the field of ships, a certain type of gas turbine supporting Parker's new material forgings has been installed in some naval ships.

After obtaining new business points, WXPK's revenue growth rate is relatively fast, from 340 million in 2016 to 653 million in 2018, with an average annual compound growth of 38.65%.

Entering military products and achieving high growth

The forging process has a wide range of uses, and can be used in many industries such as aviation, aerospace, shipping, power, petrochemicals, and other types of machinery. It is the foundation and pillar of the equipment manufacturing industry.

In the ordinary civil field, ordinary carbon steel, alloy steel, stainless steel forgings can meet the demand; high-temperature alloys, aluminum alloys, titanium alloys and other special alloy materials are often widely used in major equipment fields, such as aero engines, gas turbines, rockets, satellites, missiles …

Generally speaking, special alloy forgings used in aviation, aerospace and other industries that affect the national defense security industry are more demanding, and higher requirements are placed on the overall strength of enterprise technology. Therefore, special alloy forging has higher added value, which is not only an important guarantee for the profit margin of the enterprise, but also an important manifestation of the comprehensive technical strength of the enterprise.

In the past, almost all orders in the field of national defense and security were contracted by large state-owned military industrial enterprises or their subsidiaries. In recent years, some military equipment manufacturers have expanded the scope of supplier selection in order to diversify upstream supply risks. Some excellent forging companies in the industry seized the opportunity and successfully entered the list of suppliers of such equipment.

WXPK has become one of the few high-tech enterprises in China that can supply circular forgings in the fields of aviation, aerospace, and ships.

In the field of aviation, WXPK products have covered multiple models of aeroengines in service and in research; in the field of aerospace, WXPK has participated in the development of "Long March Series" and "Expedition Upper Class" and other carrier rockets and multiple models of missiles And supporting; in the field of ships, a certain type of gas turbine supporting WXPK forgings has been installed in some naval ships.

WXPK is also involved in the drafting of the national military standard "Specifications for Blanks of Magnesium Alloy Rings for Aerospace" and the standard "Technical Conditions for Aluminum Alloy Cone/Cylinder Rolling Forgings for Cabins" of an aerospace technology group.

WXPK can be recognized by the military, which is related to the quality of its forgings. The quality of forgings is mainly determined by the three elements of material, equipment and processing technology.

The forging materials are mainly all kinds of steel and alloy steel, which belong to the fully competitive market. Outsourcing alone makes it difficult for companies to widen the gap.

In terms of equipment, WXPK now has many high-end equipment, such as 3600T hydraulic press, 3150T fast forging machine and other presses, and 1.2m-10m precision CNC ring rolling machines. WXPK purchases 90 million worth of 7000T free forging hydraulic presses and 120 million precision ring rolling machines and other high-precision and sophisticated equipment, which can help its manufacturing level increase again.

In processing technology, WXPK has mastered 11 core technologies. Among them, the "integral precision rolling technology for special-shaped ring", "special ring rolling technology" and "ultra-large-diameter ring rolling technology" are the foundations of WXPK's foothold in the military field. These three technologies respectively solve the defects of traditional manufacturing processes in various fields and help WXPK produce forged products that meet the needs.

For example, the "integral precision rolling technology of special-shaped cross-section ring" can solve the defects of "cross-sectional profile dissatisfaction" and "outer surface folding" caused by the manufacturing process of modern advanced aircraft engine casings, and successfully prepare the shape, size, organization and performance. Meet the requirements of the overall precision shaped ring, and achieve mass production.

Because military equipment stereotypes generally go through multiple stages such as demonstration, development, testing, testing, and trial production, the verification time is very long. Therefore, before 2016, WXPK-related revenue was not high, and the aerospace industry revenue was about 10 million, which accounted for a relatively low proportion of total revenue. After 2016, the related revenue grew rapidly. In the first half of 2019, its aerospace revenue reached about 60 million.

WXPK's aerospace business can achieve such rapid growth, and this market has a large space and is fully related to growth.

The leading Chinese aviation forging market is undoubtedly AVIC Heavy Machinery, which not only leads in processing technology and equipment, but also has a revenue scale that competitors cannot match in the short term.

Due to limited market participants and limited competition, WXPK has obtained sufficient opportunities, and its related revenue has increased from 14.8834 million in 2016 to 69.58 million in the first half of 2019, with an average annual compound growth rate of 106.96%.

In addition to meeting technical standards, WXPK is also an important reason for in-depth mining of relevant customers.

In order to further expand its military products business, WXPK launched the "Production Line Project of Special Alloy Material Structural Parts for Annual Production of 5000 Tons of Aero Engines and Gas Turbines" in the second half of 2016. The project was completed in 2017 and has been put into production one after another. The basic construction was completed in the first half of 2019, mainly supporting high-end products such as aviation, aerospace and ships.

Therefore, in the field of aerospace, WXPK has also achieved good results.

In 2017, WXPK provided trial production products for the Aerospace Science and Technology Group, with a revenue of 48.392 million yuan, an increase of 467.07% over 2016. In the same year, WXPK also became a forging supplier of Aerospace Science and Industry Group.

In the first half of 2019, WXPK's aerospace forgings revenue was 55.852 million yuan, an increase of 519.58% over the first half of 2018.

WXPK civilian fields are mainly electric power field and petrochemical field. In the field of power, Parker New Material's downstream companies include wind power, thermal power, and nuclear power companies.

Nuclear power is a high-end field, and its forgings need to work under severe conditions such as high temperature, high pressure, strong neutron radiation, boric acid water corrosion, erosion, and hydraulic vibration. They have high requirements for the quality of forgings, so the added value is high. Parker New Materials hopes to have The direction of the action.

Recently, WXPK has obtained an order for DF electrical equipment of RMB 62.5 million and an order for nuclear hydrogen forgings of Dalian Hydrogenation Reactor Manufacturing Co., Ltd. of RMB 5,589,200, which has formed an important support for the future development of nuclear power forgings.

In the relatively traditional wind and thermal power market, WXPK chose the thermal power market.

The domestic terminal customers of wind power forgings are mainly the five largest power generation groups in the country. The terminal customers have a strong say in product pricing, payment time, etc., and the overall payment cycle to suppliers is long, resulting in the upstream and mid-stream suppliers returning The payment time is generally longer; in the past 4 years, Parker New Materials has actively reduced the business scale of domestic wind power forgings in order to improve the efficiency of capital use and reduce the long-term occupation of funds by wind power forgings.

The proportion of WXPK thermal power revenue has gradually increased, and the gross profit margin has also increased, from 34.57% in 2016 to 47.82% in 2018.

In addition to making choices in the power industry, WXPK puts more energy into the petrochemical industry.

In fact, there are many participants in the petrochemical forging market, and competition is fierce. However, since 2016, China's petrochemical industry has recovered and investment in the industry has increased. WXPK took the initiative to seize the opportunity of the cycle. With excellent service capabilities, excellent product quality, and flexible pricing strategies, WXPK maintained and opened up a large number of high-quality customers with better return, which led to the continuous growth of its petrochemical forging product revenue.

WXPK petrochemical-related revenue increased from 65.685 million in 2016 to 217 million in 2018, with a compound annual growth rate of 87.76%.

WXPK Company Profile

WXPK New Materials Technology Co., Ltd is a professional forging company which produces high precision forgings. The company was founded in 2006, located at Hu Dai Industrial Park, Bin Hu District, Wu Xi City, covering an area of 105,000 square meters, with registered capital 81 million RMB. There are 300 employees, and the annual sales is about 400 million RMB.

Master certification

We are certified by ISO9001:2008, GJB9001B:2009, AS9100D:2015, ISO14001:2004 EMS and OHSAS18001:2007, and also qualified by the main 9 world classification society for the factory certification and EU TUV.

Equipment capability

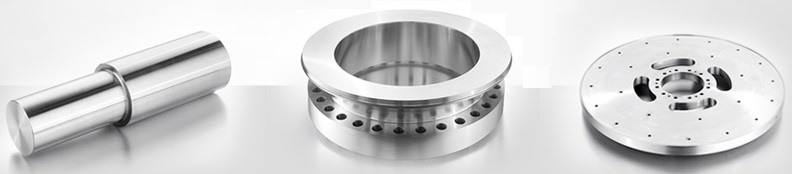

We have 230 sets of equipment in total. There are a couple of preforming presses including 3600T hydraulic press, 3150T rapid forging press; A couple of precise rolling ring mills whose diameter covers 1.2m to 10m; Many of heating furnaces, heat treatment furnaces, precise rough machining lathes, physical and chemical testing equipment, auxiliary equipment and special process equipment. Products of rolling rings with outer diameter of 300-10000mm and height of 40-1600mm can be realized which can cover all the rolling rings in recent aviation engines and gas turbine in China. The newly built production line of ring forgings is up to the standard of the international advanced design. The equipment is with high degree of automation; The layout is based on the production procedures with compact equipment structure which is to realize the low cost, high reliability and high stability of products.

Critical technology

(1) Engineering application RD for new materials has been established. Experienced material covers all the grades in recent aviation engines and gas turbine in China. Product property and uniformity of partial high-temperature alloys have reached domestic advanced level.

(2) Near-net Shape technology of rolling rings. This technology can realize precise rolling of complicated contour section rings, hard-deformed rings, super-large diameter rings, high cylinder and thin-wall rings. Forming precision of the ring forgings has achieved 3‰.

(3) Simulation technology is used in the whole process of production. Temperature field, stress field, metal flow, die stress, forming defects etc in the forming process can be simulated, which can optimize the design process and shorten the product R&D(research and development) cycle.

Main Products

The main business of our company is manufacturing ring forgings, open-die forgings,medium and small size die forgings of super alloy, titanium alloy,aluminum alloy,magnesium alloy,heat-resistant steel, stainless steel,alloy steel,carbon steel.The product services mainly in the fields of aviation, aerospace, ship building, energy power station, wind generation, petrochemical industry and engineering machinery etc.