YTTH Advanced fiber materials Tech Group Co., Ltd cover an area of 260,000 square meters, own total assets of more than 2 billion, and have more than 1200 employees. The product ranges from spandex, meta-aramid, para-aramid, anti- static fiber to aramid paper, making it the most advanced fiber production base of China.

The company specialize in the R & D and production of advanced and high performance fibers. YTTH was approved as one of the 520 key enterprises of the country. In 2008, it listed on Shenzhen Stock Exchange.

Equipped with advanced technology centers, The company have been maintaining strong capability in scientific study and innovation, having developed self-owned intellectual property rights and international advanced industrialization technology of spandex, meta-aramid fiber, para-aramid and etc.

Products

Spandex

YTTH is the main unit in drafting China National Standard of Spandex. The spandex won ‘China Top Brand’ and is the representative spandex brand in China.

spandex is produced by advanced “dry-spinning” technology, having the properties of good evenness, moderate stretch and stable quality. It is suitable for more applications than ordinary spandex.

spandex is famous for its full range of specifications and rich variety. Items from 15D to 2000D are available in dull, clear, solution dyed, anti-chlorine, easy dyeable, low stress, heat resistant and high gloss. Additional specification of spandex yarn can be produced according to customers' requirement.

the spandex is certified to Oeko-Tex Standard 100, product class I. It is a safe and healthy ecological textile material.

Meta-Aramid

The meta-aramid`s main physical properties reach international advanced level of meta-aramid products. It is awarded 'China Top Brand', and granted authorization according to Oeko-Tex Standard 100 product class 1 for baby articles. Items from 0.8d to 13d are available in raw white, solution dyed and easier dyeable in varieties of filament, tow, short-cut and staple for many different applications.

Product Category:

The raw white staple fiber

Deniers are available from 0.8D to 15D. High tensile strength and good textile properties. Suitable for high temperature resistant fabrics, scrims and outer layers of non-woven, scrims for auto hoses, sound dampers and transfer printing felts etc.

solution dyed staple fiber

solution dyed staple fiber has properties of high tensile strength and good textile. Wide varieties of colors are available against customers ’different requirements for apparels.

filament

filament is available in raw white and sage green colors .It is suitable for making apparels as well as for industrial applications like electrical insulation, rubber reinforcement, cable sheath etc.

Main Characteristics of Meta-aramid

Heat Resistance: the mata-aramid has long-lasting thermal stability. It can be used for long hours at the high temperature of 204 ℃ and maintains excellent dimensional stability. It will not embrittle, soften or melt when it is exposed temporarily to high temperature of 300 ℃.

Flame Resistance: With LOI≥28, meta-aramid is inherently flame resistant. It does not self burn or melt in the room air, no combustion-supporting, and has the property of self- extinguishing. It starts to get carbonized at 400 ℃ .

Electrical Insulation: the meta-aramid fiber has very good electrical insulation property. The dielectric strength of meta-aramid paper is up to 20kv / mm.

Chemical Stability: the meta-aramid fiber has a very stable chemical structure. It is resistant to most strong inorganic acid and to alkalis at room temperature.

Radiation Resistance: the meta-aramid fiber shows good resistance to α, β and ultraviolet radiation.

Mechanical Properties: The low-rigidity and high elongation of meta-aramid makes it available for processing by conventional textile machinery. Staple fiber can be processed into a variety of fabrics and non-wovens.

Para-Aramid

Para aramid is available in forms of filament yarn, staple fiber, short-cut, pulp and so on.

Para-aramid filament solution dyed filament and staple

para-aramid filament is available in 600Denier, 750Denier, 840 Denier, 1000 Denier, 1500 Denier, 3000 Denier, 6000 Denier and 9000 Denier.

The Para-aramid filament

para-aramid filament is available in 600Denier, 750Denier, 840 Denier, 1000 Denier, 1500 Denier, 3000 Denier, 6000 Denier and 9000 Denier.

Para-aramid Staple Fiber

para-aramid staple fiber is cut from the crimped filament. It is available in lengths of 38mm, 51mm, 76mm with linear density of 1.5D to 4D. Due to its good properties in high strength, high modulus, heat resistance and cut-proof , it is widely used for thermal resistant nonwovens, spun yarns, covering yarns etc.

Para-aramid Shortcut

Para-aramid Pulp

Para-aramid Pulp is made from Para-aramid filament (linear density of 1.5D). Due to its good properties in heat resistance, friction resistance, high strength, high modulus, it is widely used for friction and sealing materials, composites and aramid paper.

Main properties

High Strength and High Modulus

Due to the high hydrogen bonds, the strength of para aramid can reach up to above 28g / D. Its specific strength is 5-6 times that of steel wire, its specific modulus is 2-3 times that of steel wire or glass fiber, and its flexibility is 2 times that of steel wire while the weight is only 1/5 that of the steel wire.

High Temperature Resistance

para aramid can be used continuously in a very wide temperature range from -196 ℃ to 204 ℃. It has no decomposing or melting at 500 ℃. Its tenacity remains 75% after 100hours under 200 ℃.

Good Chemical Resistance

para aramid is acid and alkali resistant, anti-aging with good adhesive force in rubber.

Anti-Static Fiber

Super-strong flame resistance

With LOI over 28%, anti-static fiber is inherently flame resistant with initial temperature of carbonization up to 400 ℃. The fiber does not melt or drip in the air without toxic emission.

Excellent heat resistance

anti-static fiber does not make any changes at its conductivity below 270 ℃. It only goes down in 275 ℃ with excellent heat resistance property.

Outstanding conductivity

The specific resistance of anti-static fiber is 104 ~ 105 (Ω.cm).

Low boiling water shrinkage

The boiling water shrinkage of anti-static fiber is less than 1.5%. It can be added into textile by large percentage for the application of circumstance with high antistatic property.

Good mechanical property

anti-static fiber can be used at regular textile machine with deniers from 1D to 5D and good mechanical property. It can be possessed into random lengths with soft handle and better application in textiles.

Excellent acid and alkali resistance

anti-static fiber has good chemical resistance to most strong inorganic acid and alkalis with better alkali resistance property at normal temperature.

It maintains color consistency before and after dying process.

Aramid Paper

YTTH is a leading enterprise of the aramid paper as well as the largest first manufacturing enterprise of the aramid paper. As a hi-tech enterprise approved by Ministry of Science and Technology, the company has built some scientific research platforms, such as “Meta -aramid Application Research Lab "," National Aramid Fiber Engineering Research Center Aramid Paper Research Lab ", Aramid Fiber Engineering Technology Test Platform.

The company has complete production technology and equipment of the aramid paper with the proprietary intellectual property rights. “Meta-aramid Paper Base Material Industrialization Technology Development and Application” project was honored with “Science and Technology Progress Award (First Prize)” in 2013. At present, the company had 9 patents of invention and 4 authorized software copyrights, participated in formulating 4 state standards, of which 3 standards were headed by the company.

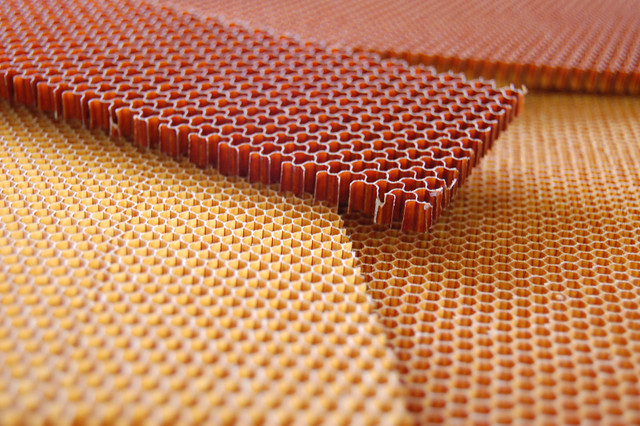

YTTH can offer full range aramid products, including Argosy Aramid Paper Honeycomb Core, meta-aramid paper, para-aramid paper, aramid pressboard, aramid crepe paper and diamond dotted paper.

Aramid paper is a special paper made of pure aramid fiber. It has the characteristics of high strength, low deformation, high temperature resistance, chemical resistance, radiation resistance, flame retardancy and excellent electrical insulation. It is widely used in aerospace and defense Industry, transportation, energy and electricity.

Due to its good mechanical properties and high temperature insulation properties, aramid paper can be divided into aramid paper for electrical insulation (YT510, YT516, YT511, YT564, YT56) and aramid paper for honeycomb core materials (YT822A, YT822, YT836) Two categories.

The aramid paper used for electrical insulation is UL-certified with a temperature resistance rating of 210 ° C. The electromechanical products made of it can achieve a temperature-resistant insulation rating above H (180 ° C). Since aramid paper does not deform at high temperatures, it does not Melting improves the ability of mechanical and electrical products to temporarily withstand excessive and overload, and the use of aramid paper as an insulating material to replace mechanical and electrical products is compact and durable, and its size and weight are greatly reduced.

Aramid insulation paper is mainly used for: insulation materials for coils in windings, interlayer insulation of windings, insulation sleeves, parts, wires and joints; insulation for coil windings, slots, phases, turns, and terminal terminations in motors and generators Materials; cable and wire insulation, insulation materials for nuclear power equipment, etc., representative products include dry-type transformers, locomotive traction motors, mine underground motors, microwave oven transformers, etc.

Aramid (Meta-Aramid/Para-Aramid) Honeycomb Cores

The aramid paper used for honeycomb core material is mainly made into aramid paper honeycomb core structure, which has the characteristics of light weight, impact resistance, high strength and aging resistance. It is mainly used for aircraft, missiles, satellite broadband transmission materials, large rigidity Force structural components (wings, fairings, cabin linings, aircraft doors, floors, cargo compartments and partition walls).