THE SUPER-LIGHT, SUPER-STRONG SUPER MAGNESIUM ALLOY

In industrial production, when it is necessary to meet the requirements for the weight and strength of the product at the same time, carbon fiber will generally become the first choice of major manufacturers. The three characteristics of light weight, high strength and corrosion resistance make carbon fiber appear to be an ideal industrial production material. However, the high cost of manufacturing carbon fiber often makes the price of carbon fiber products less affordable.

SUPER MAGNESIUM ALLOY developed by China USAL Special Alloy Research Institute has super light and super strong characteristics. Compared with traditional carbon fiber materials, Premier super magnesium alloy has the same strength and weight, but has a lower price, and is a good substitute for carbon fiber materials At the same time, compared with aluminum, super magnesium alloy is not only harder and more flexible, but also has an advantage in weight.

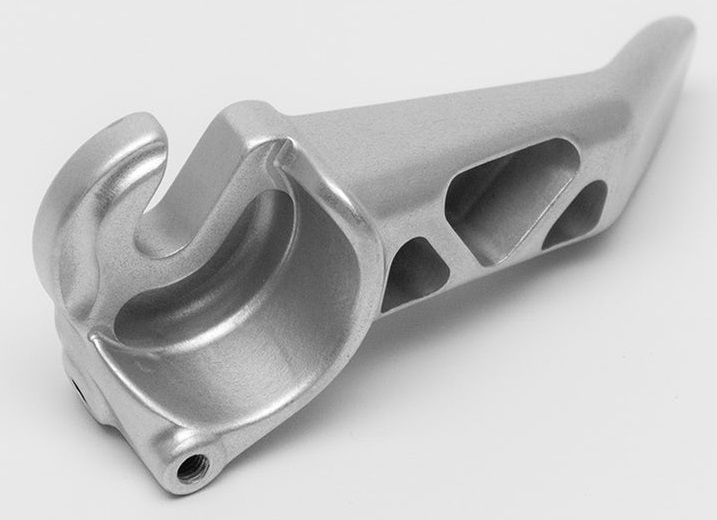

Precision Super Magnesium Alloy Parts and Components

Weighing 30% less than aluminum by volume and being both stiffer and stronger pound for pound, SUPER MAGNESIUM has incredible potential in applications where weight, performance and efficiency are critical, particularly those where components need to be strong and ductile, and have specific thermal or electrical properties while still being easy to fabricate.

In addition to its superior performance, super magnesium alloy is also a more environmentally friendly production material. In the traditional carbon fiber production process, a large amount of toxic waste gas and waste liquid will be generated, such as hydrogen cyanide and carbon monoxide; at the same time, the dust generated in the production process and the high energy consumption characteristics also make carbon fiber not a green material . In contrast, super magnesium alloy has more advantages. This material is 100% reusable. Any recovered super magnesium alloy can be directly converted into metallic magnesium for reuse. At the same time, the energy consumption of producing super magnesium alloy is only 40% of that of carbon fiber or aluminum alloy. As one of the eighth richest elements on earth, the mining and processing of magnesium is also simpler, so magnesium is recognized globally as the most environmentally friendly and sustainable metal material.

As early as 2006, super magnesium alloy has been applied in reality, but it is limited to military and aerospace production. As the technology of super magnesium alloy becomes more mature and the manufacturing cost becomes lower and lower, this new material has more applications, such as aerospace, automotive, sporting goods, electronic products, medical equipments manufacturing and many others Companies in the field.

Compared with carbon fiber products, the price of goods made of super magnesium alloy is about half that of the former. Such a huge price advantage and the excellent performance of super magnesium alloy make this material very attractive to other manufacturers.