On July 5, 2022, the graphene-modified copper-tungsten alloy material developed by GJDW Alloy Material Technology Corporation was successfully applied to the preparation of new electrical contacts for high-voltage circuit breakers.

Recently, the 252KV/63KA open-type on-column circuit breaker based on this graphene-modified copper-tungsten alloy contact part was officially put into operation in the Ningxia substation in China.

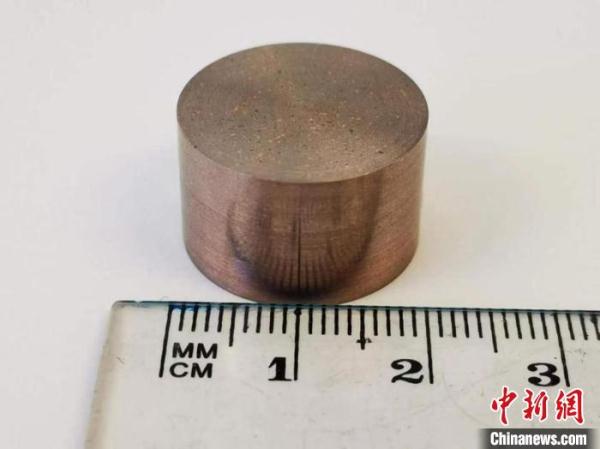

Graphene-modified copper-tungsten alloy materials prepared by vacuum sintering

According to reports, this new high-end electrical material technology is the first in the world to fill the technical gap in the field of graphene-modified high-voltage circuit breaker electrical contact materials, which can increase the full-power breaking times of high-voltage circuit breakers from 12 to 20 times. times, so as to maximize the maintenance interval of the circuit breaker, improve the availability of equipment, and reduce the cost of the whole life cycle of the system. This is very important for the protection of social electrodes.

Graphene-modified copper-tungsten alloy electrical contact product

GJDW explored chemical vapor deposition (CVD), vacuum sintering (SPS) and other composite material preparation processes, and finally optimized the vacuum infiltration method in combination with the actual situation in China, successfully prepared new materials and made finished equipment, and the finished equipment successfully passed in 2021 Type test.