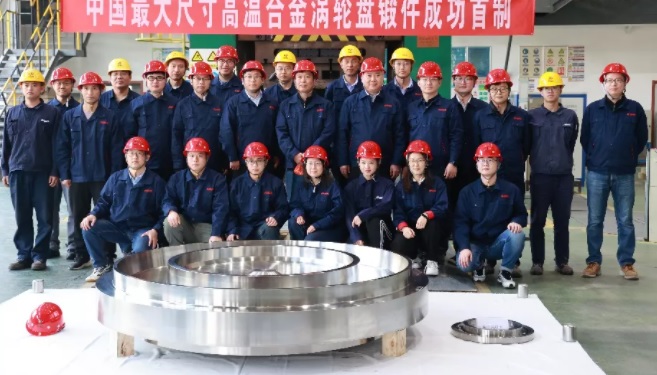

On December 30, 2021, the super-large superalloy turbine disc integral die forgings jointly developed by China GYGN Metal Material Technology Corporation, WFTG Special Steel and ZGEZ Forging Technology Corporation were successfully trial-produced, and each performance reached the same foreign alloy technology. Indicator requirements!

The turbine disc is currently the largest high-temperature alloy monolithic die forging in China, breaking the foreign monopoly. The turbine disc has a strength grade of 1200 MPa, a weight of 13.5 tons, and a diameter of 2380 mm. It is suitable for use under high temperature conditions of 650 degrees Celsius.

The core hot-forged parts of heavy-duty gas turbines for large power stations are one disc and two pieces (turbine discs and guides, working blades), which are equivalent to the "heart" of human beings. They are the key technology for gas turbine manufacturing and restrict the localization of heavy-duty gas turbines. bottleneck. The diameter and projected area of the turbine disk of a heavy-duty gas turbine are above 2.2 meters and 4.2 square meters respectively, which are 4 times the diameter of the aero engine turbine disk, 10 times the projected area, and 60 times the weight.

The project leader, Dr. Zhao, led the project team to carry out a series of basic research and technological research, using the most advanced preparation technology in the world of "triple smelting + repeated upsetting + twice upsetting + one-fire integral die forging". The implementation of international standards has broken through the technical bottlenecks encountered in the development of large-scale superalloy turbine disks, such as triple low-segregation smelting technology for large ingots weighing more than 18 tons, and repeated upsetting and fine-grain blooming technology for large bars with a diameter of 1000 mm , Integral die forging and low-temperature forming and organization control technology for large plates with a diameter of more than 2200 mm.

Aiming at metallurgical defects such as extremely high alloying element Nb content in superalloys, black spots and white spot segregation, the team carried out independent research and development, original innovation, and initially formed an independent intellectual property software system for the preparation of super-large turbine disks, which solved China's heavy-duty The "technical bottleneck" problem of the key hot-end components of gas turbines has opened up a process route for the preparation of large-scale deformed superalloy turbine disks with Chinese characteristics with independent intellectual property rights.