SZAL Advanced Materials Technology Corporation is committed to R&D and the production of high-performance nanocomposite materials. It is a global leader in vacuum coating equipment, coating technology, nanocomposite reinforcement and other fields, providing customers with customized solutions.

SZAL was founded by two PhDs from prestigious American universities. The founding team has hundreds of papers and patents in the semiconductor industry, data storage technology and touch display, vacuum coating equipment design, and thin film materials. It has 20 years of scientific research in national laboratories and experience in the industrialization of Silicon Valley.

The water-proof and oxygen-barrier multifunctional composite film developed exclusively by the company is the world's highest technical level and best performance in the same field. This composite film at the molecular level takes the copolymer polymer chain as the body, and the surface is covered with a dense nano-thin layer, and the body polymer chain introduces functional molecules that can absorb ultraviolet and anti-oxidation to achieve waterproof (salt-proof) Anti-corrosion, etc.), oxygen resistance, UV resistance (can be used outdoors), high temperature resistance (increasing the use temperature of the traditional protective film from less than 100 ℃ to 150 ℃) and other excellent performance.

The new composite film materials developed by the company and the supporting large-scale industrialization research results can provide customers with a package of protection solutions for electronic products, ensuring that their products can be used outdoors and worry-free around the clock. The new protective film can also be used in the production of flexible OLED screens to increase the water and oxygen resistance of the substrate and package, and extend the service life.

Consumer electronics industry application solutions

The waterproof and oxygen-barrier multifunctional composite film provides comprehensive protection for consumer electronic products such as smart phones, tablet computers, and earphones. The electronic components inside electronic products, mainly electronic circuit boards (PCBA), are protected by vacuum coating to isolate the contact between water and electronic devices and achieve the purpose of protection. Even if water enters the electronic product, it will not harm the internal components.

Industrial industry application solutions

The UV-resistant and high-temperature composite protective film can uniformly wear a layer of dense "protective clothing" as thin as a cicada wing on electronic components, thereby improving industrial electronic equipment such as LED displays, automotive control components, drones, and shipboards. The reliability of electronic equipment used in harsh environments can enable users to safely use electronic products in all weathers and regions.

Medical industry application solutions

The waterproof and oxygen barrier multifunctional composite membrane has passed RoHS and US FDA certification, and can be implanted in the human body. The waterproof and oxygen-barrier multifunctional composite membrane has good thermal and chemical stability, and can be widely used in various medical devices such as implantable biochips, cardiac pacemakers, pressure sensors….

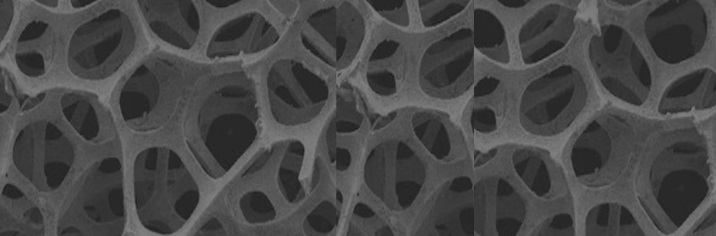

Ultra-light and super-strong composite material is another new type of material developed by SZAL. This material has the characteristics of high specific strength, good impact resistance, sound insulation and heat insulation, fire resistance and flame retardant. It can be widely used in high-rise building walls, wind turbine blades, high-speed rail aircraft seats, automobiles and yachts and Implantable medical stent...

Porous and similar to honeycomb material