On September 28, 2021, China`s first self-developed new superconducting cable was put into use in Shenzhen. This is also the world`s first superconducting cable used in the central area of a super-large city, marking that China has fully mastered the design of new superconducting cables. , The key core technology of manufacturing and construction.

Small size and large capacity, which can meet the electricity demand of 4 high-speed trains at the same time

As early as 1911, Dutch scientist Onnes discovered superconductors, but because their critical temperature is close to absolute zero (about minus 273°C), it is difficult to apply them. After the 1980s, high-temperature superconducting materials with a critical temperature in the liquid nitrogen temperature region around minus 200°C were discovered, and the application fields of superconductors have been greatly expanded.

Professor Dai Shaotao, Director of the Applied Superconducting Technology Research Center of Beijing Jiaotong University, explained: “Of course, the'high temperature' here is relative to absolute zero. But liquid nitrogen can be obtained relatively easily and cheaply, so high temperature superconductivity is important. Application value."

High-temperature superconducting power transmission technology is known as the next generation of power transmission strategic technology, which has the advantages of low line loss, large transmission capacity, small corridor area, and environmental friendliness. The power transmission capacity of a 10-kV three-coaxial high-temperature superconducting AC cable is greater than that of a conventional 110-kV cable, but the transmission loss is only 1/4 to 1/5 of that of a conventional cable.

The new superconducting cable put into use in Shenzhen this time has a diameter of only 17.5 cm and a length of 400 meters, with a transmission capacity of up to 43 MVA, which is equivalent to meeting the electricity demand of four 350 kilometers per hour high-speed rail at the same time, achieving 5 times that of conventional cables. The power transmission capacity of China has brought high-reliability power supply to the Shenzhen Ping An Financial Center, the tallest building in the Guangdong-Hong Kong-Macao Greater Bay Area.

Superconducting cable laying process

It occupies a small area and uses less materials, providing a new solution for power supply in large-scale cities with high-load density areas

In recent years, the power supply in the central areas of super-large cities around the world is facing challenges. The load demand in central urban areas continues to grow, the demand for "double reduction" in energy consumption is increasing year by year, the saturation of urban corridors, and the difficulty of land use for power grid construction have been exposed year by year. Shenzhen is the city with the largest electricity load density in China, and the load density of its central business district is even "peak on peak".

"If the existing power supply method is adopted, it is necessary to supply power to the important loads in the Futian central area, especially the newly added loads, and use conventional technology to achieve expansion, which is very difficult in Shenzhen, which is very expensive." China Southern Power Grid Shenzhen Power Supply Bureau Innovation and According to Lu Zhining, general manager of the Digitalization Department, 10 kV superconducting cables can reduce the use of high-voltage cables in the urban power grid while meeting the power supply requirements, simplify the grid structure, reduce the construction of 110 kV substations, and save 500 square meters of land. The "package" solves the practical problems of high power supply reliability, high load density, high power quality, and limited land resources.

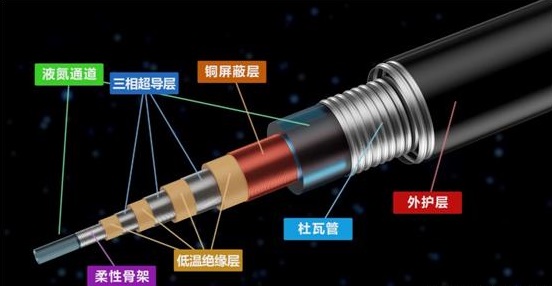

Superconducting cable adopts three same axis configuration

The superconducting cable developed and put into production this time adopts the three-axis configuration, which is the superconducting cable with the most compact structure, the least amount of strips, and the most difficult research and development. After 4 years, the project team has made major breakthroughs in the overall design and manufacture of superconducting cable systems, and the development of domestically produced large refrigeration GM refrigerators through independent innovation, and achieved 100% localization of key equipment, filling the domestic technology. blank.

Hay Think learned from SZNF Superconducting Cable Technology Company that, as a major scientific and technological project of SZNF, it will provide a new solution for the global power supply problem of large cities with high load density. Compared with conventional technology, the high-temperature superconducting demonstration project put into production this time has basically reached an economic equilibrium point.